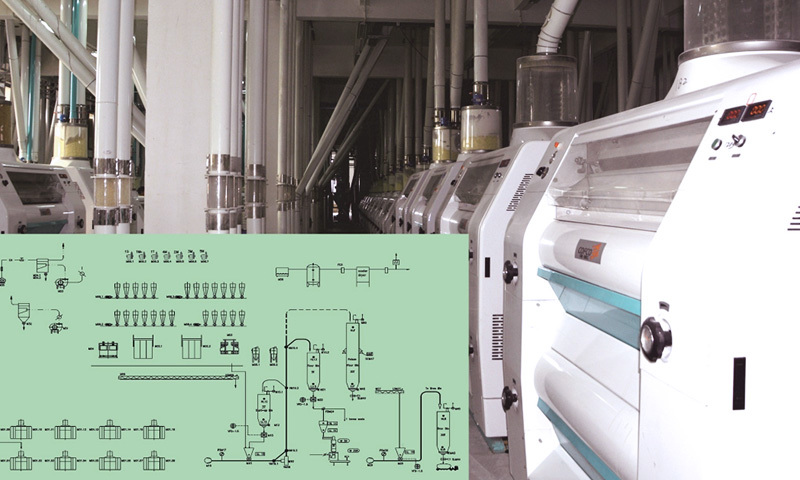

Wheat Milling

The composition of the complete set of flour milling equipment is different from that of the single flour machine, the process design is more sophisticated, the rate of flour is higher, and it can produce grades of flour, with the output ranging from 10T/D to 1,000T/D, which can meet the actual needs of different users.

Milling Process

01

Wheat

Wheat will be mixed with impurities in the process of growth, harvesting, storage and transportation, such as soil, sand and weed seeds. These impurities must be thoroughly removed to ensure the quality of the flour. The cleaning process includes the use of wind selection, vibration screening, wheat beating, stone removal, wheat washing and other steps.

02

Pre-cleaning and filter

Wheat will be mixed with impurities in the process of growth, harvesting, storage and transportation, such as soil, sand and weed seeds. These impurities must be thoroughly removed to ensure the quality of the flour. The cleaning process includes the use of wind selection, vibration screening, wheat beating, stone removal, wheat washing and other steps.

03

Milling

The wheat is milling by to separate the endosperm from the wheat skin (peel and seed coat) and embryo. The process consists of two main stages of core-milling and derm-milling, in which the mill breaks the wheat into different parts, such as large bran, small bran, large endosperm, small endosperm, etc., and then goes to different mills for further grinding, combined with sifting and cleaning.

04

Sieving and grading

The flour after grinding is sent to the screening machine for screening to remove impurities and bran from the flour.

05

Drying

The sifted flour is sent to the dryer for drying to remove the moisture in the flour and improve the quality and warranty period of the flour.

06

Powder mixing

According to the customer's demand for special powder, different wheat flour is mixed in a certain proportion to change the powder characteristics of the target wheat flour and meet the specific quality requirements.

07

Package

The final wheat flour is packaged for easy storage and transportation

08

Flour

Solution Features

Removal of impurities

The raw grain is cleaned by a combination of various means to maximize the removal of impurities;

Easy to operate

Sophisticated equipment, easy operation and maintenance; good airtightness, perfect dust removal design, dust does not rise, that is, to ensure the effect of the process and environmental health and make the workshop bright and simple.

Advanced technology

Advanced technology, skin milling system to extract a large number of good quality coarse grain, coarse powder, try to ensure the integrity of the bran; and focus on the use of clean powder machine, improve the purity of the heart grinding material, to ensure that the rate of high-quality powder;

High quality

High product quality, high output rate, low power consumption, and can meet the requirements of various grades of powder, special powder production;

Automation

High degree of automation, the main data in the equipment can be collected to the WeChat platform of the user's cell phone; based on the remote operation and maintenance management of the equipment, the customer can realize the remote monitoring of the equipment operation data on the mobile terminal, which is convenient, easy to use and safe.

Solution Strength

Complete process design

Perfect powder making process design, excellent equipment, to meet the higher needs of users;

Intelligent control system

Advanced PLC intelligent control system realizes intelligent and automatic production of modern factory.

Tailor-made programmes

According to the customer's demand, we can design two types of building structure and steel structure. (The building structure is suitable for large-scale and extra-large-scale flour milling plants, and the steel structure is suitable for small and medium-scale flour milling plants.)

Related Projects

HOW CAN WE HELP ?

Get In Touch With Us!

Contact Information

Fax: +86-371-23227333

E-mail: global@aomgmach.com

Production base: Zongdian Industrial Zone, Qi County, Kaifeng City