Recent Posts

Why Powder Conveying Systems are Essential for Modern Agriculture

Release time:

Jun 27,2025

Why Powder Conveying Systems are Essential for Modern Agriculture Table of Contents 1. Introduction to Powder Conveying Systems 2. The Importance of Powder Conveying Systems in Agriculture 2.1 Enhancing Efficiency in Agricultural Processes 2.2 Boosting Productivity and Output 3. Types of Powder Conveying Systems 3.1 Pneuma

Why Powder Conveying Systems are Essential for Modern Agriculture

Table of Contents

- 1. Introduction to Powder Conveying Systems

- 2. The Importance of Powder Conveying Systems in Agriculture

- 3. Types of Powder Conveying Systems

- 4. Applications of Powder Conveying Systems in Agriculture

- 5. Key Benefits of Implementing Powder Conveying Systems

- 6. Challenges in Powder Conveying Systems

- 7. The Future of Powder Conveying in Agriculture

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Powder Conveying Systems

In the fast-evolving world of agriculture, efficiency and innovation are paramount. **Powder conveying systems** have emerged as a vital component in the agricultural machinery landscape. These systems primarily facilitate the movement of bulk powders, grains, and granulated materials, streamlining processes and improving overall productivity. With advancements in technology, these systems have become integral to various agricultural operations, making them indispensable for modern farming.

2. The Importance of Powder Conveying Systems in Agriculture

The role of powder conveying systems in agriculture cannot be overstated. These systems provide numerous benefits that directly impact farming efficiency and productivity.

2.1 Enhancing Efficiency in Agricultural Processes

One of the primary advantages of powder conveying systems is their ability to enhance efficiency. Automated powder handling reduces the need for manual labor, minimizing human error and the risk of contamination. This automation ensures that materials move swiftly from one stage of production to another, saving time and resources.

2.2 Boosting Productivity and Output

By facilitating quick and reliable transport of bulk materials, powder conveying systems significantly boost productivity. High-capacity systems can handle large volumes of material simultaneously, meeting the increasing demands of modern agriculture. This enhanced capability allows farmers to focus on other essential aspects of their operations, leading to increased output and profitability.

3. Types of Powder Conveying Systems

Understanding the different types of powder conveying systems is crucial for selecting the right solution for your agricultural needs. Below are the main types used in modern agriculture:

3.1 Pneumatic Conveying Systems

Pneumatic conveying systems utilize air pressure or vacuum to transport powders and granules. These systems are highly efficient and can cover long distances. They minimize product degradation and are suitable for fragile materials, making them a popular choice in agricultural settings.

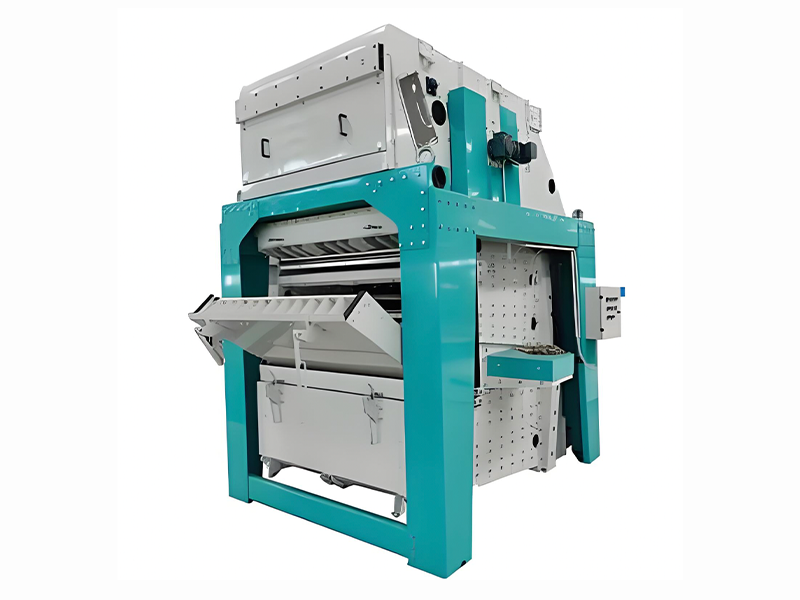

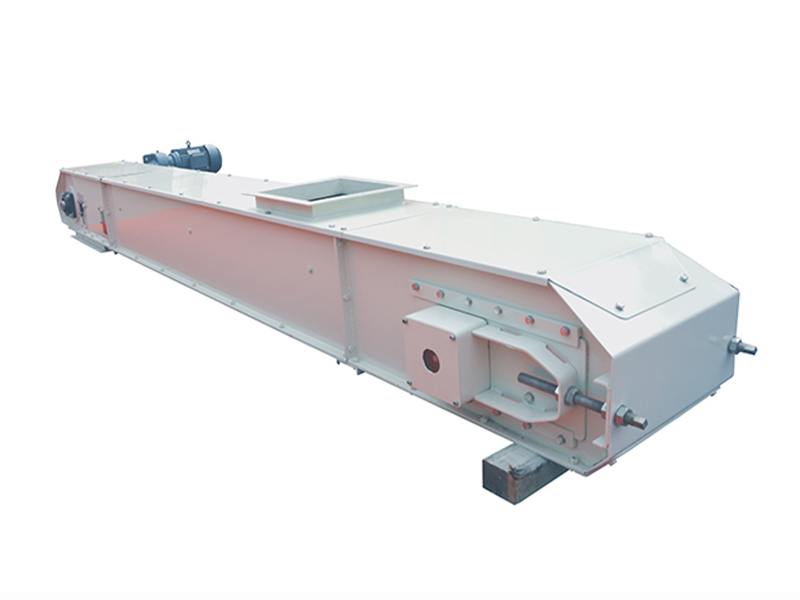

3.2 Mechanical Conveying Systems

Mechanical systems, such as screw conveyors and belt conveyors, are ideal for horizontal or inclined transport of bulk materials. These systems offer versatility and can handle various materials, making them an excellent option for farms that deal with different types of grains and powders.

3.3 Vibratory Conveying Systems

Vibratory conveyors use vibration to move materials along a surface. These systems are particularly beneficial for delicate powders, ensuring gentle handling without causing damage. They are commonly used in applications where precise feeding and controlled flow are required.

4. Applications of Powder Conveying Systems in Agriculture

Powder conveying systems find a wide range of applications within the agricultural sector. Their versatility makes them suitable for various tasks:

- **Feed Handling:** Powder conveying systems transport animal feed efficiently, ensuring that livestock has access to the necessary nutrients.

- **Fertilizer Distribution:** These systems are used to move fertilizers from storage to application points, facilitating timely and accurate application.

- **Seed Processing:** In seed processing facilities, powder conveying systems streamline the movement of seeds, enhancing productivity in planting operations.

- **Grain Transport:** Powder conveying systems are vital for transporting grains from harvesting to storage, ensuring quality and minimizing spoilage.

5. Key Benefits of Implementing Powder Conveying Systems

Implementing powder conveying systems offers a multitude of benefits for modern agricultural practices:

- **Reduced Labor Costs:** Automation of material handling reduces the need for manual labor, freeing up workers for other critical tasks.

- **Improved Hygiene Standards:** Closed systems minimize dust and contamination, promoting better hygiene and safety.

- **Energy Efficiency:** Many modern systems are designed to optimize energy consumption, reducing operational costs.

- **Increased Flexibility:** The adaptability of powder conveying systems allows farmers to handle a variety of materials and processes.

6. Challenges in Powder Conveying Systems

While powder conveying systems offer numerous advantages, they are not without challenges. Some common issues include:

- **System Maintenance:** Regular maintenance is crucial to avoid breakdowns and ensure smooth operation. Neglect can lead to costly downtimes.

- **Material Characteristics:** Different powders have unique flow properties. Selecting an inappropriate system may lead to inefficiencies.

- **Initial Investment:** The upfront cost of installing a powder conveying system can be significant, requiring careful financial planning.

7. The Future of Powder Conveying in Agriculture

As technology continues to advance, the future of powder conveying systems in agriculture looks promising. Innovations such as smart sensors and IoT integration are expected to enhance system performance and efficiency. Additionally, the push for sustainable farming practices will drive the development of eco-friendly conveying solutions that reduce energy consumption and environmental impact.

8. Frequently Asked Questions (FAQs)

What are powder conveying systems?

Powder conveying systems are mechanical or pneumatic setups used to transport bulk powders and granulated materials efficiently within agricultural processes.

How do pneumatic conveying systems work?

Pneumatic conveying systems utilize air pressure or vacuum to move powders through pipelines, allowing for quick and efficient transport.

What are the advantages of using mechanical conveying systems?

Mechanical conveying systems, such as screw or belt conveyors, offer versatility in handling various materials and can be configured for different transport routes.

Can powder conveying systems improve safety in agriculture?

Yes, by minimizing manual handling and reducing dust exposure, powder conveying systems enhance safety and hygiene standards in agricultural operations.

What challenges might I face when implementing a powder conveying system?

Challenges may include maintenance needs, the specific characteristics of materials being conveyed, and the initial investment required for system installation.

9. Conclusion

Powder conveying systems are essential for modern agriculture, providing efficiency, productivity, and safety in material handling processes. With the ability to streamline operations and handle various agricultural materials, these systems play a pivotal role in the industry's evolution. As technology continues to advance, investing in robust powder conveying solutions will undoubtedly yield significant benefits for farmers and agribusinesses alike. Embracing these systems not only enhances operational efficiency but also positions agricultural enterprises at the forefront of modern farming practices.

keywords

HOW CAN WE HELP ?

Get In Touch With Us!

Contact Information

Fax: +86-371-23227333

E-mail: global@aomgmach.com

Production base: Zongdian Industrial Zone, Qi County, Kaifeng City

Business license