Recent Posts

Understanding the Costs Associated with Ton Bag Unpacking Conveyors: A Comprehensive Guide

Release time:

Jul 25,2025

Understanding the Costs Associated with Ton Bag Unpacking Conveyors Table of Contents 1. Introduction to Ton Bag Unpacking Conveyors 2. Importance of Efficient Unpacking Solutions in Agriculture 3. Key Factors Influencing the Costs of Ton Bag Unpacking Conveyors 4. Initial Investment Costs of Ton Bag Unpacking Conveyors 5. Operational Costs: What to Expect 6. Maintenance Costs and Bes

Understanding the Costs Associated with Ton Bag Unpacking Conveyors

Table of Contents

- 1. Introduction to Ton Bag Unpacking Conveyors

- 2. Importance of Efficient Unpacking Solutions in Agriculture

- 3. Key Factors Influencing the Costs of Ton Bag Unpacking Conveyors

- 4. Initial Investment Costs of Ton Bag Unpacking Conveyors

- 5. Operational Costs: What to Expect

- 6. Maintenance Costs and Best Practices

- 7. Evaluating the Return on Investment (ROI)

- 8. Strategies for Cost Optimization in Unpacking Processes

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Ton Bag Unpacking Conveyors

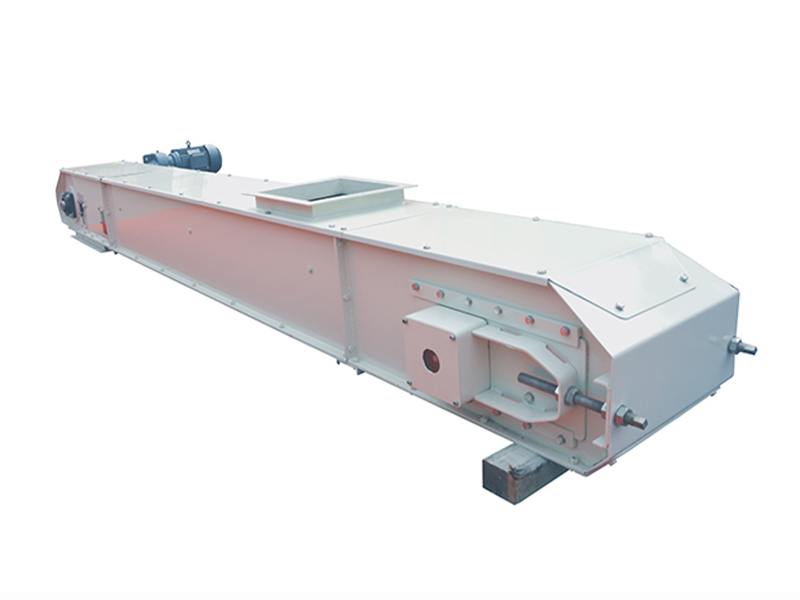

Ton bag unpacking conveyors play a crucial role in the agricultural sector, particularly in the efficient handling of bulk materials. These specialized conveyors streamline the unloading process, significantly reducing manual labor and improving operational efficiency. Understanding the costs associated with these systems is essential for any agricultural business looking to enhance productivity while managing expenses.

2. Importance of Efficient Unpacking Solutions in Agriculture

The agricultural industry relies heavily on the timely and efficient movement of materials. As farms scale up their operations, the need for automated solutions like ton bag unpacking conveyors becomes paramount. Efficient unpacking systems help minimize downtime, reduce labor costs, and improve the overall workflow, resulting in better resource management.

3. Key Factors Influencing the Costs of Ton Bag Unpacking Conveyors

Several factors contribute to the overall cost of ton bag unpacking conveyors. Understanding these factors can help businesses make informed decisions:

3.1 Equipment Type and Specifications

The type of conveyor system, whether it’s a gravity feed, powered, or bespoke solution, significantly influences the cost. Specifications such as length, width, and load capacity play a role in determining the right system for your needs.

3.2 Material Quality and Durability

Using high-quality materials ensures longevity and reliability. Although premium materials may have higher upfront costs, they often lead to lower maintenance expenses and extended service life.

3.3 Installation Requirements

The complexity of the installation process can also impact costs. Factors like site preparation, existing infrastructure, and required modifications can add to the overall expense.

3.4 Labor Costs

While ton bag unpacking conveyors reduce the need for manual labor, initial installation and ongoing maintenance will still require skilled labor, which can add to operational costs.

4. Initial Investment Costs of Ton Bag Unpacking Conveyors

Investing in a ton bag unpacking conveyor system involves several upfront costs. These can be broken down into:

4.1 Purchase Price

The purchase price varies widely based on the system's complexity and brand. Basic models may start at a lower price point, while advanced systems with automation features can be significantly more expensive.

4.2 Installation and Setup

Installation costs can include labor fees and equipment needed for setup. Businesses should estimate these costs ahead of time to avoid budget overruns.

4.3 Additional Equipment

In some cases, additional equipment, such as feeders or hoppers, may be necessary to integrate with the conveyor system.

5. Operational Costs: What to Expect

Operational costs encompass the everyday expenses associated with running a ton bag unpacking conveyor system:

5.1 Energy Consumption

These systems require electricity to function. Understanding energy efficiency ratings can help predict and manage ongoing energy costs.

5.2 Labor for Operation

Even with automation, some labor will be required to oversee the operations, especially during the initial phases of implementation.

5.3 Materials Handling

Incorporating efficient materials handling practices can optimize the conveyor's functionality, impacting the overall operational costs positively.

6. Maintenance Costs and Best Practices

Maintaining ton bag unpacking conveyors is essential for longevity and performance. Regular maintenance can mitigate costly repairs and downtime:

6.1 Routine Inspections

Conducting regular inspections helps identify potential issues before they escalate. This proactive approach can save businesses money in the long run.

6.2 Replacement Parts

Understanding the costs of replacement parts is crucial. Keeping an inventory of essential components can minimize operational disruptions.

6.3 Professional Maintenance Services

Hiring professionals for maintenance can ensure that the equipment remains in optimal condition. While this incurs an expense, it often pays off through enhanced efficiency and reduced breakdowns.

7. Evaluating the Return on Investment (ROI)

Calculating the ROI of investing in ton bag unpacking conveyors involves understanding both the tangible and intangible benefits:

7.1 Increased Efficiency

The primary advantage is increased efficiency in materials handling, leading to higher productivity and potentially greater profits.

7.2 Labor Cost Savings

While initial costs may be high, the long-term savings on labor can significantly enhance ROI.

7.3 Improved Material Quality

Efficient handling reduces the risk of product damage, thereby improving overall material quality and reducing waste.

8. Strategies for Cost Optimization in Unpacking Processes

To maximize the benefits of ton bag unpacking conveyors, employing cost optimization strategies is essential:

8.1 Invest in Quality Equipment

Opt for reliable and durable conveyor systems to reduce maintenance and replacement costs.

8.2 Staff Training

Invest time in training staff to use machinery efficiently, minimizing errors that could lead to increased operational costs.

8.3 Monitor Performance Metrics

Regularly track performance metrics to identify areas for improvement and optimize processes accordingly.

9. Frequently Asked Questions

9.1 What is a ton bag unpacking conveyor?

A ton bag unpacking conveyor is a specialized system designed to facilitate the efficient unloading of bulk materials from ton bags, streamlining the process of moving materials within agricultural operations.

9.2 How much does a ton bag unpacking conveyor cost?

The cost varies based on factors such as size, type, and complexity, with basic models starting at lower prices and advanced systems potentially exceeding several thousand dollars.

9.3 What are the maintenance requirements for these systems?

Regular inspections, timely replacement of worn parts, and professional maintenance services are critical to ensure the longevity and efficiency of the conveyor systems.

9.4 Can ton bag unpacking conveyors improve my farm’s productivity?

Absolutely. By minimizing manual handling and optimizing the unloading process, these conveyors can significantly enhance productivity and reduce labor costs.

9.5 How do I determine the right conveyor system for my operation?

Consider factors such as the type and volume of materials to be handled, available space, and your budget to find a system that meets your operational needs effectively.

10. Conclusion

Understanding the costs associated with ton bag unpacking conveyors is crucial for making informed investment decisions in the agricultural sector. By considering factors such as initial investment, operational costs, and maintenance, businesses can maximize their efficiency and reduce expenses. Implementing cost optimization strategies will not only enhance productivity but also pave the way for long-term success. Embracing this technology is a step forward in achieving a more efficient and profitable agricultural operation.

keywords

Previous Page:

Previous Page:

HOW CAN WE HELP ?

Get In Touch With Us!

Contact Information

Fax: +86-371-23227333

E-mail: global@aomgmach.com

Production base: Zongdian Industrial Zone, Qi County, Kaifeng City

Business license