Recent Posts

How a Horizontal Wheat Scourer Significantly Enhances Your Milling Process

Release time:

Jul 11,2025

How a Horizontal Wheat Scourer Significantly Enhances Your Milling Process Table of Contents 1. Introduction to Horizontal Wheat Scourers 2. The Importance of Wheat Scouring in Milling 3. Why Choose a Horizontal Design? 4. Working Principle of a Horizontal Wheat Scourer 5. Key Benefits of Using a Horizontal Wheat Scourer 6. Installation Tips for Optimal Performance

How a Horizontal Wheat Scourer Significantly Enhances Your Milling Process

Table of Contents

- 1. Introduction to Horizontal Wheat Scourers

- 2. The Importance of Wheat Scouring in Milling

- 3. Why Choose a Horizontal Design?

- 4. Working Principle of a Horizontal Wheat Scourer

- 5. Key Benefits of Using a Horizontal Wheat Scourer

- 6. Installation Tips for Optimal Performance

- 7. Maintenance Practices for Longevity

- 8. Conclusion

- 9. FAQs

1. Introduction to Horizontal Wheat Scourers

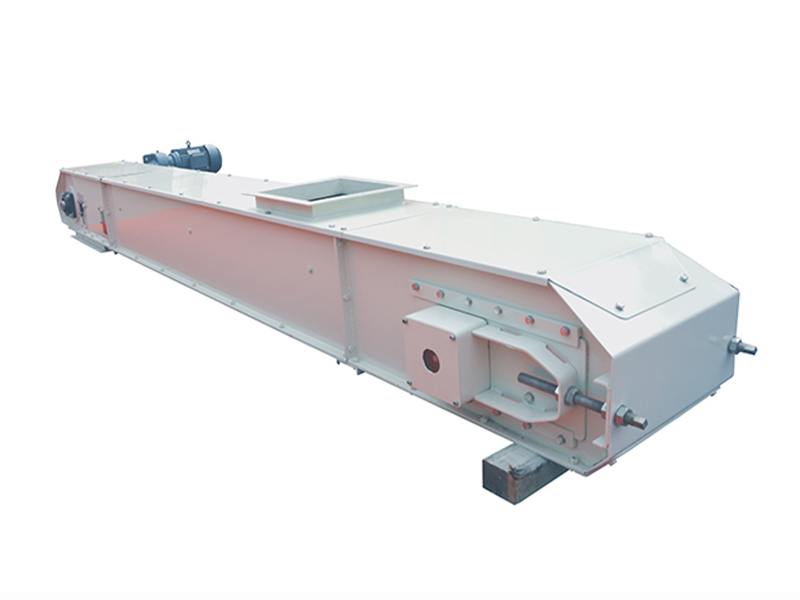

The milling industry has seen numerous advancements aimed at enhancing efficiency and product quality. Among these innovations, the **horizontal wheat scourer** stands out as a vital piece of equipment that significantly improves the milling process. This article explores how this machine functions, its advantages, and why it should be an essential part of any milling operation.

2. The Importance of Wheat Scouring in Milling

Wheat scouring is a crucial step in the milling process. It involves removing impurities, dust, and foreign materials from wheat grains before they are processed into flour. Effective scouring leads to higher flour quality, better milling yields, and a reduction in wear on milling equipment. By ensuring that the grain is clean, millers can produce flour that meets both quality standards and customer expectations.

3. Why Choose a Horizontal Design?

Horizontal wheat scourers offer several advantages over their vertical counterparts. Here are some reasons why the horizontal design is preferred:

3.1 Enhanced Efficiency

Horizontal scourers facilitate better material flow, allowing for **more even distribution** of grain within the machine. This results in improved cleaning rates and overall efficiency during the scouring process.

3.2 Reduced Energy Consumption

Due to their design, horizontal scourers often require less energy to operate. This not only lowers operational costs but also makes them an environmentally friendly choice, as less energy consumption translates to a smaller carbon footprint.

3.3 Space Optimization

Horizontal scourers typically occupy less vertical space, making them suitable for facilities with height restrictions. This allows for **strategic placement** in milling operations without compromising on performance.

4. Working Principle of a Horizontal Wheat Scourer

Understanding the working principle of a horizontal wheat scourer is essential for maximizing its benefits. The machine operates through a series of **mechanical actions** designed to effectively remove contaminants from the wheat:

4.1 Grain Movement

As grain enters the scourer, it is fed into a horizontal chamber where it moves along a conveyor or auger system. This movement allows for optimal exposure to the scouring elements.

4.2 Scrubbing Action

Inside the chamber, the grain is subjected to a scrubbing action, typically facilitated by rubber or metallic paddles. These paddles gently agitate the grain, helping to dislodge impurities without damaging the kernels.

4.3 Airflow System

A well-designed airflow system is critical for effective cleaning. Air is introduced into the chamber to help remove lighter contaminants, such as dust and husks, which are then expelled through a discharge outlet.

5. Key Benefits of Using a Horizontal Wheat Scourer

Integrating a horizontal wheat scourer into your milling process provides several significant benefits:

5.1 Improved Grain Quality

By effectively removing contaminants, a horizontal scourer enhances the overall quality of the wheat, leading to superior flour. Clean wheat results in better baking properties, aroma, and shelf life.

5.2 Increased Milling Efficiency

With a cleaner product entering the milling phase, the overall efficiency of the milling process is improved. This can lead to higher yields and lower operational costs.

5.3 Enhanced Equipment Longevity

By minimizing impurities entering the milling equipment, horizontal scourers reduce wear and tear, subsequently extending the lifespan of costly machinery.

5.4 Consistency in Production

With improved grain quality and reduced variations in input, millers can expect a more consistent product, which is crucial for maintaining brand reputation and customer loyalty.

6. Installation Tips for Optimal Performance

To ensure that your horizontal wheat scourer functions optimally, consider the following installation guidelines:

6.1 Location Selection

Choose a location that allows adequate space for operation and maintenance. Ensure that the scourer is positioned close to the grain intake area to minimize transportation time.

6.2 Proper Alignment

Ensure that the scourer is installed level and aligned with other components of the milling system. Misalignment can lead to inefficiencies and increased wear.

6.3 Electrical and Air Supply

Confirm that the electrical and airflow systems are correctly set up to provide the necessary power and ventilation for optimal operation.

7. Maintenance Practices for Longevity

Regular maintenance is essential to keep your horizontal wheat scourer running efficiently. Follow these practices:

7.1 Routine Inspections

Conduct regular inspections to check for wear on paddles and other moving parts. Address any signs of wear promptly to prevent further damage.

7.2 Cleaning Protocols

Implement a cleaning routine to remove accumulated dust and residues. A clean machine operates better and enhances the overall efficiency of the milling process.

7.3 Lubrication

Ensure that all moving parts are properly lubricated according to the manufacturer’s specifications. Proper lubrication minimizes friction and enhances performance.

8. Conclusion

Incorporating a **horizontal wheat scourer** into your milling process can yield significant advantages, from improved grain quality to enhanced operational efficiency. By understanding its working principles and following best practices for installation and maintenance, millers can fully capitalize on the benefits offered by this essential piece of equipment. Embracing such innovations not only optimizes the milling process but also positions businesses for sustained success in a competitive industry.

9. FAQs

9.1 What is a horizontal wheat scourer?

A horizontal wheat scourer is a machine designed to clean wheat grains by removing impurities, dust, and foreign materials before milling.

9.2 How does a horizontal wheat scourer work?

It uses mechanical agitation and airflow to scrub the wheat grains and expel contaminants, ensuring a cleaner product for milling.

9.3 What are the benefits of using a horizontal wheat scourer?

Benefits include improved grain quality, increased milling efficiency, enhanced equipment longevity, and consistent production.

9.4 How often should I maintain my horizontal wheat scourer?

Regular maintenance should occur according to a set schedule, with more frequent checks during peak operation periods.

9.5 Can a horizontal wheat scourer reduce operational costs?

Yes, by improving efficiency and reducing wear on equipment, it can lower energy consumption and maintenance costs over time.

keywords

HOW CAN WE HELP ?

Get In Touch With Us!

Contact Information

Fax: +86-371-23227333

E-mail: global@aomgmach.com

Production base: Zongdian Industrial Zone, Qi County, Kaifeng City

Business license